Utility Boiler

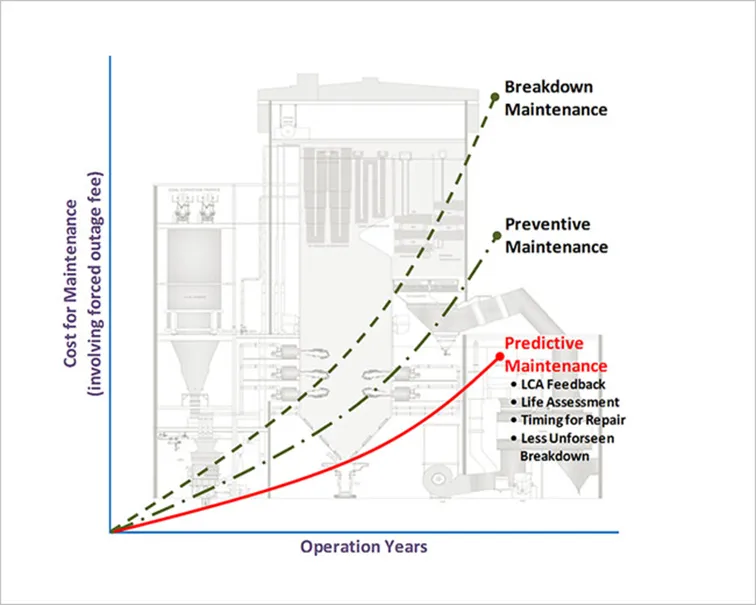

"Predictive Maintenance"

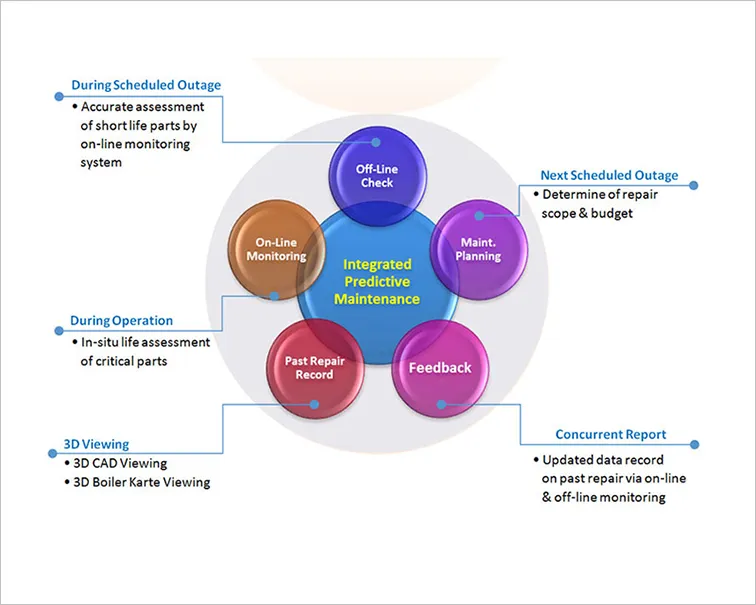

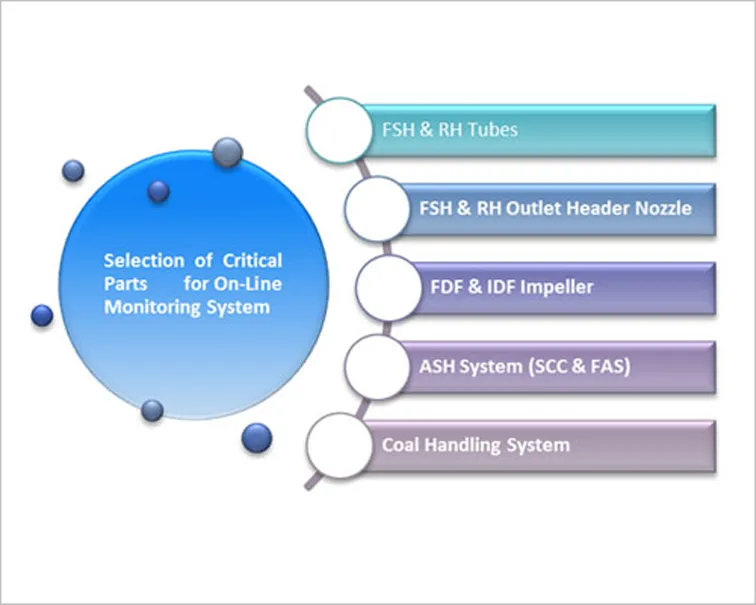

Advanced Predictive Maintenance has been introduced for utility boiler in Malaysia. The system comprises combination of on-line monitoring system realizing of “Visualization of life” and off-line inspection to accomplish more precise life assessment.